Cohesion 2

Cohesion 2

Cohesion 2

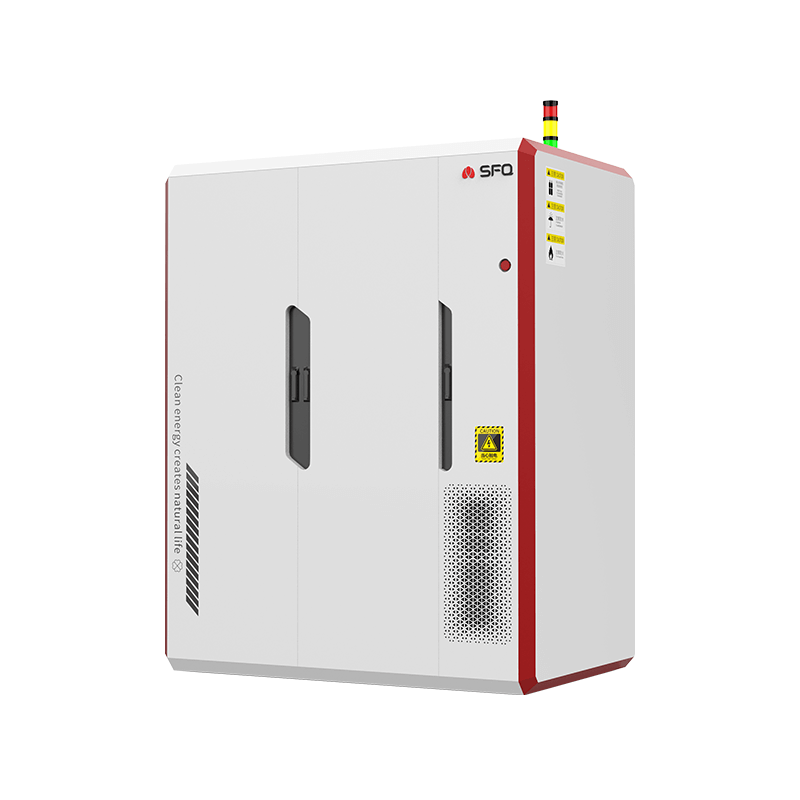

PV Energy Storage System is an all-in-one outdoor energy storage cabinet that integrates a LFP battery, BMS, PCS, EMS, air conditioning, and fire protection equipment. Its modular design includes a battery cell-battery module-battery rack-battery system hierarchy for easy installation and maintenance. The system features a perfect battery rack, air-conditioning and temperature control, fire detection and extinguishing, security, emergency response, anti-surge, and grounding protection devices. It creates low-carbon and high-yield solutions for various applications, contributing to building a new zero-carbon ecology and reducing businesses’ carbon footprint while improving energy efficiency.

PRODUCT FEATURE

-

Active Battery Balancing Management Technology

This technology ensures that each cell in the battery pack is charged and discharged evenly, which maximizes the battery's capacity and extends its lifespan. It also helps prevent overcharging or undercharging, which can lead to safety hazards or reduced performance.

-

BMS with Millisecond Response Time

The Battery Management System (BMS) accurately measures State of Charge (SOC), State of Health (SOH), and other critical parameters with millisecond response time. This ensures that the battery operates within safe limits and provides reliable performance.

-

Car Grade Battery Cells with Double Safety Features

The battery pack uses high-quality car grade battery cells that are designed for durability and safety. It also features a two-layer pressure relief mechanism that prevents overpressure and a cloud monitoring system that provides quick warnings in case of any issues.

-

Comprehensive Digital LCD Display

The battery pack comes with a comprehensive digital LCD display that shows real-time information about the battery's performance, including SOC, voltage, temperature, and other parameters. This helps users monitor the battery's health and optimize its usage.

-

BMS Collaborative Security Control Technology

The BMS collaborates with other safety systems in the vehicle to provide comprehensive security control. This includes features such as overcharge protection, over-discharge protection, short circuit protection, and temperature protection.

-

BMS Collaborative Cloud Platform for Battery Cell Status Visualization

The BMS collaborates with a cloud platform that enables visualization of battery cell status in real-time. This helps users monitor the battery's health remotely and detect any issues before they become critical.

PRODUCT PARAMETERS

| Model |

SFQ-E241

|

| PV parameters | |

| Rated power | 60kW |

| Max input power | 84kW |

| Max input voltage | 1000V |

| MPPT voltage range | 200~850V |

| Starting voltage | 200V |

| MPPT lines | 1 |

| Max input current | 200A |

| Battery parameters | |

| Cell type | LFP 3.2V/314Ah |

| Voltage | 51.2V/16.077kWh |

| Configuration | 1P16S*15S |

| Voltage range | 600~876V |

| Power | 241kWh |

| BMS communication interface | CAN/RS485 |

| Charge and discharge rate | 0.5C |

| AC on grid parameters | |

| Rated AC power | 100kW |

| Max input power | 110kW |

| Rated grid voltage | 230/400Vac |

| Rated grid frequency | 50/60Hz |

| Access method | 3P+N+PE |

| Max AC current | 158A |

| Harmonic content THDi | ≤3% |

| AC off grid parameters | |

| Max output power | 110kW |

| Rated output voltage | 230/400Vac |

| Electrical connections | 3P+N+PE |

| Rated output frequency | 50Hz/60Hz |

| Max output current | 158A |

| Overload capacity | 1.1 times 10min at 35℃/1.2times 1min |

| Unbalanced load capacity | 100% |

| Protection | |

| DC input | Load switch+Bussmann fuse |

| AC converter | Schneider circuit breaker |

| AC output | Schneider circuit breaker |

| Fire protection | PACK level fire protection+smoke sensing+temperature sensing, perfluorohexaenone pipeline fire extinguishing system |

| General parameters | |

| Dimensions (W*D*H) | 1950mm*1000mm*2230mm |

| Weight | 3100kg |

| Feeding in and out method | Bottom-In and Bottom-Out |

| Temperature | -30 ℃~+60 ℃ (45 ℃ derating) |

| Altitude | ≤ 4000m (>2000m derating) |

| Protection grade | IP65 |

| Cooling method | Aircondition (liquid cooling optional) |

| Communication interface | RS485/CAN/Ethernet |

| Communication protocol | MODBUS-RTU/MODBUS-TCP |

| Display | Touch screen/cloud platform |