SFQ e Phahamisa Tlhahiso e Bohlale ka Ntlafatso e Kholo ea Mohala oa Tlhahiso

Re thabetse ho phatlalatsa ho phetheloa ha ntlafatso e felletseng moleng oa tlhahiso oa SFQ, e leng se tšoaeang tsoelo-pele e kholo bokhoning ba rona. Ntlafatso ena e akaretsa libaka tsa bohlokoa tse kang ho hlophisa lisele tsa OCV, kopano ea lipakete tsa betri, le ho tjheseletsa li-module, ho beha maemo a macha a indasteri mabapi le bokgabane le polokeho.

Karolong ea ho hlophisa lisele tsa OCV, re kopantse lisebelisoa tsa ho hlophisa tse iketsang tsa sejoale-joale tse nang le pono ea mochini le li-algorithms tsa bohlale ba maiketsetso. Tšebelisano ena ea theknoloji e nolofalletsa ho khetholla ka nepo le ho arola lisele ka potlako, ho netefatsa ho khomarela litekanyetso tse thata tsa boleng. Lisebelisoa li na le mekhoa e mengata ea tlhahlobo ea boleng bakeng sa tlhahlobo e nepahetseng ea liparamente tsa ts'ebetso, e tšehetsoang ke mesebetsi ea ho lekanya ka boiketsetso le temoso ea liphoso ho boloka ts'ebetso e tsoela pele le botsitso.

Karolong ea ho hlophisa lisele tsa OCV, re kopantse lisebelisoa tsa ho hlophisa tse iketsang tsa sejoale-joale tse nang le pono ea mochini le li-algorithms tsa bohlale ba maiketsetso. Tšebelisano ena ea theknoloji e nolofalletsa ho khetholla ka nepo le ho arola lisele ka potlako, ho netefatsa ho khomarela litekanyetso tse thata tsa boleng. Lisebelisoa li na le mekhoa e mengata ea tlhahlobo ea boleng bakeng sa tlhahlobo e nepahetseng ea liparamente tsa ts'ebetso, e tšehetsoang ke mesebetsi ea ho lekanya ka boiketsetso le temoso ea liphoso ho boloka ts'ebetso e tsoela pele le botsitso.

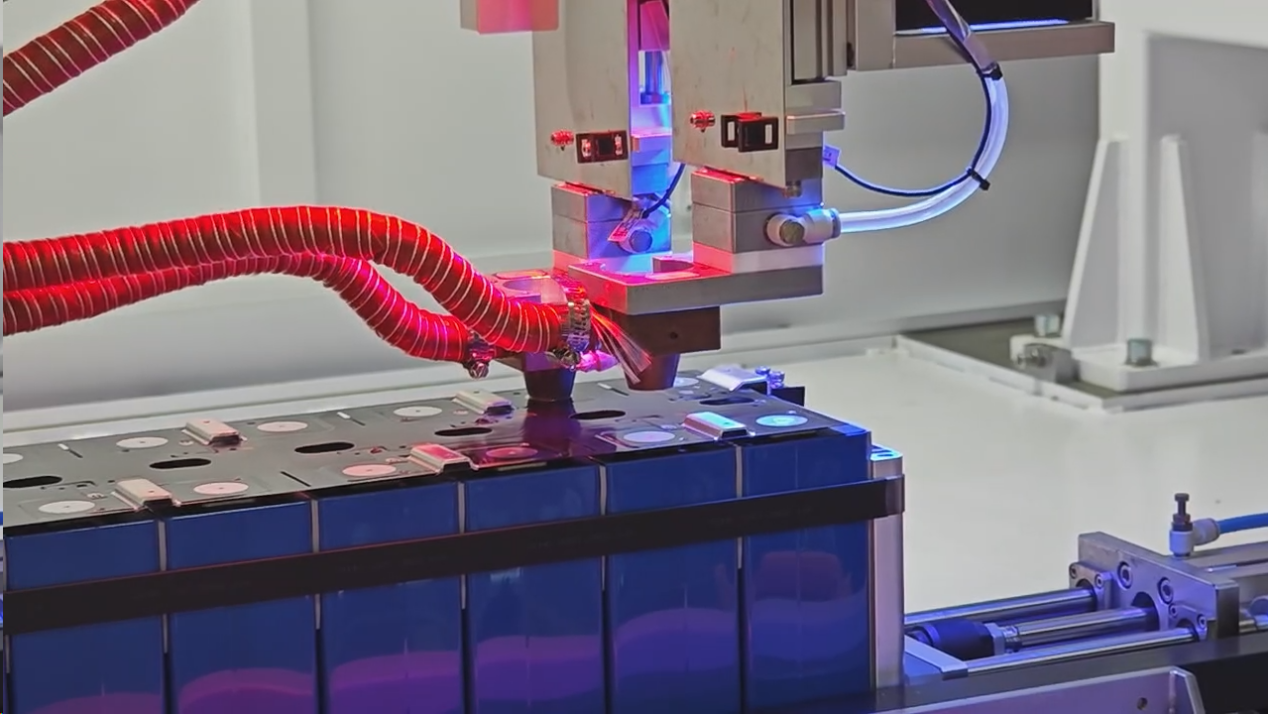

Sebaka sa rona sa ho kopanya lipakete tsa betri se bonts'a boqhetseke ba theknoloji le bohlale ka mokhoa oa moralo oa modular. Moralo ona o ntlafatsa ho tenyetseha le bokhoni ts'ebetsong ea ho kopanya. Ka ho sebelisa matsoho a roboto a iketsang le theknoloji ea ho beha hantle, re fihlella kopano e nepahetseng le liteko tse potlakileng tsa sele. Ho feta moo, sistimi e bohlale ea polokelo e nolofatsa tsamaiso le phano ea thepa, e eketsang katleho ea tlhahiso.

Sebaka sa rona sa ho kopanya lipakete tsa betri se bonts'a boqhetseke ba theknoloji le bohlale ka mokhoa oa moralo oa modular. Moralo ona o ntlafatsa ho tenyetseha le bokhoni ts'ebetsong ea ho kopanya. Ka ho sebelisa matsoho a roboto a iketsang le theknoloji ea ho beha hantle, re fihlella kopano e nepahetseng le liteko tse potlakileng tsa sele. Ho feta moo, sistimi e bohlale ea polokelo e nolofatsa tsamaiso le phano ea thepa, e eketsang katleho ea tlhahiso.

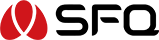

Karolong ea ho tjheseletsa mojule, re amohetse theknoloji e tsoetseng pele ea ho tjheseletsa ka laser bakeng sa likhokahano tsa mojule tse se nang sekoli. Ka ho laola ka hloko matla le tsela eo lehlaseli la laser le tsamaeang ka eona, re netefatsa hore ho tjheseletsa ho se na sekoli. Ho beha leihlo boleng ba ho tjheseletsa ho sa khaotseng hammoho le ho kenya tšebetsong alamo hang-hang haeba ho ka ba le lintho tse sa tloaelehang ho netefatsa polokeho le ts'epo ea ts'ebetso ea ho tjheseletsa. Thibelo e matla ea lerōle le mehato e khahlanong le ho sisinyeha e matlafatsa boleng ba ho tjheseletsa.

Karolong ea ho tjheseletsa mojule, re amohetse theknoloji e tsoetseng pele ea ho tjheseletsa ka laser bakeng sa likhokahano tsa mojule tse se nang sekoli. Ka ho laola ka hloko matla le tsela eo lehlaseli la laser le tsamaeang ka eona, re netefatsa hore ho tjheseletsa ho se na sekoli. Ho beha leihlo boleng ba ho tjheseletsa ho sa khaotseng hammoho le ho kenya tšebetsong alamo hang-hang haeba ho ka ba le lintho tse sa tloaelehang ho netefatsa polokeho le ts'epo ea ts'ebetso ea ho tjheseletsa. Thibelo e matla ea lerōle le mehato e khahlanong le ho sisinyeha e matlafatsa boleng ba ho tjheseletsa.

Ntlafatso ena e felletseng ea mohala oa tlhahiso ha e matlafatse feela bokhoni ba rona ba tlhahiso le katleho empa hape e beha polokeho pele. Mehato e mengata ea tšireletso ea polokeho, e kenyeletsang lisebelisoa, polokeho ea motlakase le tikoloho, e kentsoe tšebetsong ho netefatsa tikoloho e sireletsehileng le e tsitsitseng ea tlhahiso. Ho feta moo, koetliso e ntlafalitsoeng ea polokeho le maano a tsamaiso bakeng sa basebetsi a matlafatsa temoho ea polokeho le bokhoni ba ts'ebetso, e fokotsa likotsi tsa tlhahiso.

SFQ e ntse e tiile boitlamong ba rona ba "boleng pele, moreki pele ho tsohle," bo inehetseng ho faneng ka lihlahisoa le lits'ebeletso tsa boleng bo holimo. Ntlafatso ena e bontša khato ea bohlokoa leetong la rona la ho ea bokhabane boleng le ho ntlafatsa tlholisano ea mantlha. Ha re sheba pele, re tla matlafatsa matsete lipatlisisong le nts'etsopele, re hlahise mahlale a tsoetseng pele, 'me re tsamaise tlhahiso e bohlale maemong a sa tloaelehang, ka hona re theha boleng bo ntlafalitsoeng bakeng sa bareki ba rona.

Re leboha batšehetsi bohle le bareki ba SFQ ka botebo. Ka cheseho e phahameng le boiphihlelo bo sa thekeseleng, re ikana ho tsoela pele ho fana ka lihlahisoa le lits'ebeletso tse ntle. A re kopaneng ho theha bokamoso bo khanyang hammoho!

Nako ea poso: Hlakubele-22-2024